Description

In order to provide products having convincingly compact dimensions, we developed the PDD® Technology. PDD stands for Piezoelectric Direct Discharge. It is based on the direct, electric discharge at an openly operated piezoelectric transformer (PT).

By means of PDD®Technology, low input voltage is transformed. This results in high electric field strengths. The ambient process gas – typically air – is dissociated and ionized.

The advantages of the direct discharge control are obvious: The excitation of gas molecules is highly efficient and safe. Furthermore, the power density of the compact device is extremely high. In practice, a processing performance level is now achieved that had previously been possible only by means of considerably larger installations. This is the ideal device for manual applications in laboratories, medical technology, in commerce and in industry.

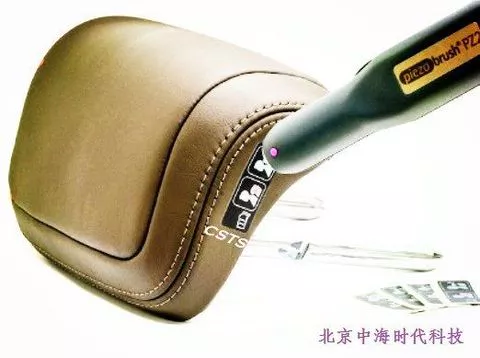

The piezobrush®has been conceived for application by end-users. Herein, RP plasma has paid particular attention to usability and user-friendliness. The piezobrush®requires no specialist, technical knowledge and no complex infrastructure.

Standard Device for Manual Use

The piezobrush®has been conceived to be an efficient handheld unit. At a maximum power consumption of 30W, cold active plasma with a temperature of ~ 50°C is generated. The piezo brush®stands out due to its low-maintenance construction principle. All individual components are characterized by their long-term durability and do not need to be replaced or maintained.

The piezobrush®is also very suitable for being used in professional model making and the manual assembly of small lots. Glueing of synthetic materials becomes easier due to surface activation resulting from the impact of cold plasma.

Surface activation with cold active plasma for example allows simultaneous activation of PSA (pressure sensitive adhesive) and substrate surface. Also the adhesion of coatings in the automotive field of application or on polypropylene is optimized.

As a further advantage, prior treatment with the piezobrush®handheld unit increases the bonding strength in the case of epoxy-based adhesives being used for glueing materials, such as glass, GRP, ABS and other synthetic materials.

Due to the low thermal stress, treatment of materials conventionally used in model making – such as wood and various kinds of paper – using all-purpose power glue is excellent.

- Plasma generator

- Plasma

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

Beijing CSTS Technology Co.,Ltd

Not informed

Not informed

Not informed

Year

Established

Business type

- Importer / Trading Company

- Representative / Agent

- Distributor / Wholesaler

- Business Service

Keywords

- csts1203

Contact and location

-

Vivian Chen

-

+86 10 xxxxxxxx

-

Beijing / Beijing | China