Description

Loading capacity (Max.) 10.0 m3

Microwave generator power 60 kW

Drying control system (optional) ControlSystems

Magnetron CK-2131

Conveyor capacity 200 m3

Energy consumption 20-40 kWh

Generator size1200 х 1200 х 2100 mm

Internal chamber size 6600 х Ø 1700 mm

Chamber size 7000 х 1800 х 2000 mm

Drying time

Oak boards 50 mm - 36 hours

Oak board 100 mm - 48 hours

Beech boards 50 mm - 30 hours

Beech boards 100 mm - 40 hours

Pine, Cedar and Fir 200 mm - 24 hours

Description

Fast drying cycle;

Automatic feeder;

Large capacity;

Automated systems with touch screen control panel;

Uniform heating;

No sparking or bending problem;

Suitable for drying logs, beams and boards, hard and softwoods;

Automatic feeding system;

Full drying wood is 5-8%;

Shrinkage is 3-5%;

Price 54 000 USD;

You can purchase a lease for a period of 12 to 36 months.

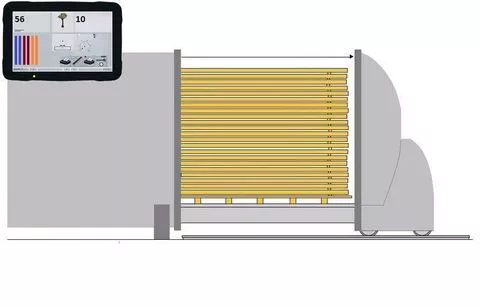

SVCHVD-75-EU — This is a highly compact, reliable and powerful microwave Vacuum chamber for drying lumber of any species and sizes. Small dimensions, a power supply of microwave energy and excellent specific power of vacuum guarantee high productivity when working with wood of both soft and hard rocks. Precise automatic control increases the efficiency of the chamber.

Sturdy construction SVCHVD-75-EU, with automatic loading of the carriage and powerful power supply of ultra-high frequencies (915 Hz) provide high performance and long service life. Thanks to ControlSystems produces high-precision measurements before and after drying the sawn timber. Work on the development of the drying chamber was carried out in cooperation with customers and was focused on simplicity in management and maintenance.

Drying chamber with a short cycle of operation, devoid of many drawbacks of convective and vacuum technology. It is designed for dehydration of sawn timber of any kind. In the design of the chamber consists of a body of cylindrical shape with built-in waveguides to supply the microwave energy generated by the microwave generator. The use of microwave energy for wood dewatering is very promising for today, since microwave wave energy causes rapid heating inside the tree, accompanied by an excessive growth of internal vapor pressure. This technology is capable of removing water from the capillary system and the fibers of the tree.

- microwave vacuums drying chamber

- kiln dried logs

- kiln dried wood

- kiln dried

- wood kiln

- vacuum drying

- seasoned logs

- kiln dried lumber

- kiln dried hardwood

- wood drying kiln

Production Capacity:

12

Delivery Timeframe:

Within 90 Days

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

CIP - Carriage and Insurance Paid to

CPT - Carriage Paid to

DAF - Delivered At Frontier

DDP - Delivered Duty Paid

DDU - Delivered Duty Unpaid

DEQ - Delivered Ex Quay

DES - Delivered Ex Ship

EXW - Ex Works

FAS - Free Along Ship

FCA - Free Carrier

FOB - Free on Board

Packaging Details:

Not informed

More about

AIM Wood UG

50-100

Employees

200K - 500K

Sales volume (USD)

60%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- drying chamber for wood

- microwave

- vacuum

- Magnetron

- plasma

- composite heater Ver Mais

Contact and location

-

Artur ********

-

+1 800********

-

Skagway, / AL | United States