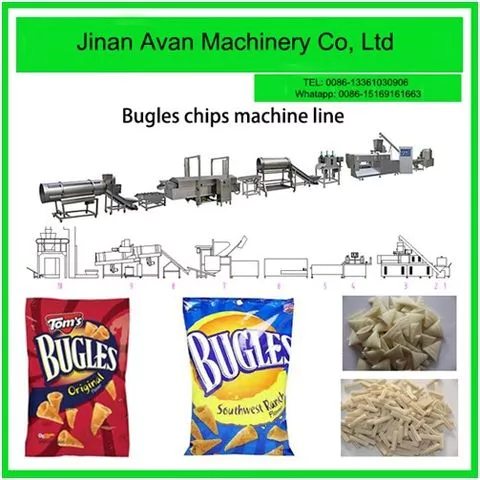

Description

Automatic fried corn bugle snacks production line

Machine Instruction:

Bugles chips process line uses corn powder, corn starch, and rice powder as main materials which are extruded, punched into triangle, round, square shapes, and then baked and flavored. Such snacks with crispy taste, rich nutrition and digestible structure are very popular with many people all over the world. And most important, the waste punching chip can be reused after grinding into powder, which can greatly reduce the production cost.

Raw materials: Corn powder, rice powder, starch, ect

Products: Chips, bugles, sala chips, 3d chips.

With different shapes and taste by changing the dies, formulations.

Machine Flow Chart:

Mixer machine--Hoister--Extruder--Belt conveyor--Shaper machine---Fryer machine--Oil sprayer--Flavoring machine--Packing machine

- bugles machine

Production Capacity:

20

Delivery Timeframe:

Within 60 Days

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

CIP - Carriage and Insurance Paid to

EXW - Ex Works

FAS - Free Along Ship

FCA - Free Carrier

FOB - Free on Board

Packaging Details:

Wooden

More about

Jinan Avan Machinery Co., Ltd

10-50

Employees

100K - 200K

Sales volume (USD)

60%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Importer / Trading Company

Keywords

- Extruder machine

- Dryer oven

- Puff snacks line

- Cheetos machine

- Fry chips machine

- Soya protein machine

- Microwave oven. Ver Mais

Contact and location

-

Carl ********

-

+86 13********

-

Jinan / Shandong | China