Description

We specialize in multiple impeller prototyping and rapid manufacturing technologies, providing CNC machining, 3D printing, vacuum casting, rapid aluminum and alloy machining molds, low-volume CNC processes, and sheet metal machining.

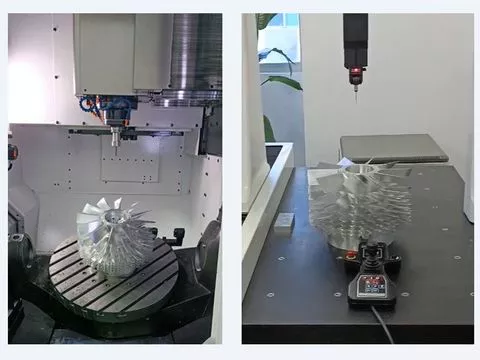

High-precision machining - impeller rapid prototyping

01. Comprehensive CNC machining

Equipped with machines with a stroke of more than 1 meter, combined with the best combination of 3-, 4-, and 5-axis CNC milling machines, we have the expertise to perfectly machine custom parts for impellers.

02. Prototypes achieve high accuracy

KeSuRapid offers a wide range of cost-effective precision solutions to choose from. Rapid processing enables the integration of two or more materials.

A CNC manufacturing team of professional engineers and machinists to optimize NC programming and efficient toolpaths.

5-axis continuous CNC machining, providing higher machining accuracy and flexibility.

We pay attention to every design detail; The blades and hub details are machined to a minimum radius of R0.10mm.

Excellent surface quality, finished surface finish Ra (μm) 0.2, surface tolerance ± 0.025mm.

Auxiliary EDM machining is necessary to meet the overall machining requirements of impeller parts.

- Impeller

- Impeller Machining

- CNC Machining

- Mold Making

- 3D Printing

- Sheet Metal Processing

- Injection Molding

- Die Casting

- Surface Treatment

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

Kesu Hardware Group Co., Ltd

Not informed

Not informed

Not informed

Year

Established

Business type

- Industry / Manufacturer

Keywords

- CNC machining

- Mold manufacturing

- 3D printing

- Sheet metal processing

- Injection molding

- Die casting

- Surface treatment Ver Mais

Contact and location

-

Jams ********

-

+86 1********

-

Dongguan / China | China