Description

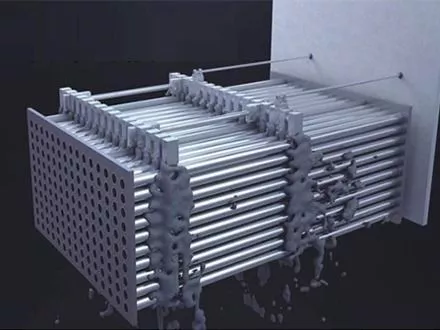

Air pre-equipment is an important equipment in power plant generator sets. With the more stringent national environmental protection requirements, power plants will mostly increase the desulfurization, denitrification link, but this link will cause the air pre-equipment blockage and corrosion. Below by the empty pre-factory detailed the reasons for the tube-type empty pre-device congestion.

1. The adhesion of hydrogen sulfate

The urea solution injected into the furnace by denitrification does not fully react with nitrogen oxides, causing ammonia to escape, and ammonia reacts with sulfur trioxide in the tail flue to form hydrogen sulfate, when the exhaust temperature drops to 145 degrees C to 2 At 05 degrees C, hydrogen sulfate is converted to liquid, liquid hydrogen sulfate has a strong viscosity, so the region's flue gas fly ash will adhere to the pipe wall of the tube-type air precursor, resulting in the pipe wall block ash or plate knot.

2. The corrosive ash of the sulphide is blocked

Most of the coal contains sulfur, in the combustion will produce sulfur trioxide, sulfur trioxide will be combined with the water vapor in the flue gas, and thus form sulfuric acid steam, when the pipe wall temperature is lower than the sulfuric acid steam dew point, the formation of acid will corrode the air precursor pipe wall, low temperature corrosion will be accompanied by low temperature ash.

3. The ash blower works with water

The blowtorch is a common way to deal with tube-type empty pre-emption to block ash. However, when the dust blower is working with water, it can not only solve the problem of empty pre-device clogging effectively, but also aggravate the problem of empty pre-device clogging. Boiler in the process of blowing ash, because steam blowing ash work is slow, and from top to bottom in turn, the time spent is longer, generally up to 1.5 to 2 hours, which will lead to lower ash blowing steam pipe temperature reduction, resulting in steam condensation into water. When blowing the lower layer of the empty precursor, because the steam with a large amount of water, will capture the fly ash attached to the pipe wall, with the increase in the number of steam blowing ash work, over time will also cause the air precursor pipe wall ash accumulation is serious.

Empty pre-plant blockage will seriously affect the heat exchange effect, resulting in boiler load reduction operation, serious also will cause the boiler to stop furnace. Therefore, the power plant every time the boiler stop furnace maintenance will use a variety of ways to solve the problem of empty pre-machine blockage, tube-type air pre-pre-blockage management has been more concerned about the power plant.

At present, most of the ways and means to solve the problem of empty pre-device blockage on the market need to be implemented when the boiler stops the furnace, and the frequency of the plant stop furnace is high, which will inevitably affect the economic benefits of the power plant. Therefore, at present, independent research and development of an on-line clean-up of empty pre-emption ash products, can not stop furnace on the empty pre-emption of ash treatment, to a large extent to extend the boiler stop cycle, improve the production efficiency of the boiler.

- air preheater

- ash cleaning device

- superheater

- economize

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

Shandong Hongjiang Intelligent Equipment Co., Ltd

Not informed

Not informed

Not informed

Year

Established

Business type

- Industry / Manufacturer

- Distributor / Wholesaler

- Business Service

Keywords

- Air preheater

- air preheater

- ash cleaning device

- superheater

- economizer

Contact and location

-

yanhua ********

-

+86 1********

-

taian / shandong | China