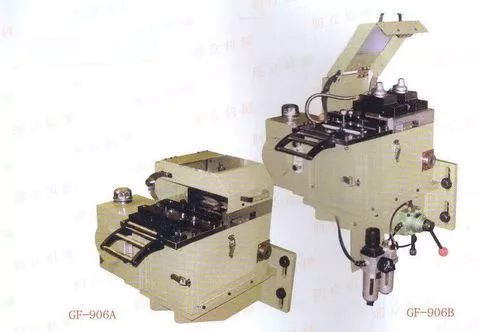

Description

<br />

Features:<br />

<br />

It is suitable for straightening all kinds of high precision metal material.<br />

This machine is the powerful new equipment which is used for high speed press work.And it can advavce pressing product's quality and quantity.<br />

Fine electric parts can not be finished with high accuracy unless straightened coil materials may achieve.So Roll material need to be straightened,and the stress be moderately removed.<br />

After being straightened,materials can be curled upward or downward or flat easily.<br />

As bearings of work-rolls are,of a oiling,lubricating free type,there will be no trouble from the adherence of oil or dirt.<br />

The drive unit is controlled by an inverters(cycle control) to feed smoothly at a speed synchronized with the press.<br />

Two sections type straightening device,it is no need to adjust straighten function when rolled materi al is under straightening process(from start to end).To ensure the material at same flatness completely.<br />

We Accept Special Purposed Machine Orders.<br />

Adopt transducer timing,which is can running placidity.<br />

<br />

<br />

SPECIFICATIONS<br />

ModelsGJ10-100GJ10-200<br />

<br />

Max.Width(mm)100200<br />

Max.Thickness(mm)0.05-0.30.05-0.3<br />

Reducer1:1.51:1.5<br />

Motor(HP)1/21/2<br />

PowerAC three-phase voltage 380V<br />

Straighten Rollers19<br />

Adjustment4-Point Micro-adjustment<br />

Speed AdjustmentFrequency Converter<br />

*Right of modification reserved.<br />

*All specifications,dimensions and design characteristics shown in this page are subject to rechange without notice.

- feeder

- feeding machine

- straightener

- uncoiler

- decoiler

- straightening machine

- press machine

- hardware

- metal products

Production Capacity:

www.mzfeeder.com

Delivery Timeframe:

Within 30 Days

Incoterms:

CFR - Cost and Freight

Packaging Details:

Features:

It is suitable for straightening all kinds of high precision metal material.

This machine is the powerful new equipment which is used for high speed press work.And it can advavce pressing product's quality and quantity.

Fine electric parts can not be finished with high accuracy unless straightened coil materials may achieve.So Roll material need to be straightened,and the stress be moderately removed.

After being straightened,materials can be curled upward or downward or flat easily.

As bearings of work-rolls are,of a oiling,lubricating free type,there will be no trouble from the adherence of oil or dirt.

The drive unit is controlled by an inverters(cycle control) to feed smoothly at a speed synchronized with the press.

Two sections type straightening device,it is no need to adjust straighten function when rolled materi al is under straightening process(from start to end).To ensure the material at same flatness completely.

We Accept Special Purposed Machine Orders.

Adopt transducer timing,which is can running placidity.

SPECIFICATIONS

ModelsGJ10-100GJ10-200

Max.Width(mm)100200

Max.Thickness(mm)0.05-0.30.05-0.3

Reducer1:1.51:1.5

Motor(HP)1/21/2

PowerAC three-phase voltage 380V

Straighten Rollers19

Adjustment4-Point Micro-adjustment

Speed AdjustmentFrequency Converter

*Right of modification reserved.

*All specifications,dimensions and design characteristics shown in this page are subject to rechange without notice.www.mzfeeder.com

More about

Suzhou Ming Zhong Machinery Co., Ltd.

50-100

Employees

1M - 2M

Sales volume (USD)

30%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- feeder

- feeding machine

- straightener

- uncoiler

- decoiler

- straightening machine

- press machine

- hardware

- metal products Ver Mais

Contact and location

-

Tan ********

-

+86 51********

-

Suzhou / Jiangsu | China