Description

Geomembrane with plastic film as an impermeable substrate, and non-woven composite of the geo-impermeable material, new material geomembrane its impermeable properties mainly depends on the anti-penetration performance of plastic film. At present, the plastic film of anti-penetration applicationats at home and abroad, mainly PVC (PVC) and polyethylene (PE), EVA (ethylene/vinyl acetate copolymer), tunnel applications also have the design of the use of ECB (ethylene acetate modified asphalt conjugate membrane), they are a polymer chemical flexible material, the proportion of small, strong elongation, high adaptability, corrosion resistance, low temperature, good antifreeze performance.

Brief introduction.

Geomembrane is a waterproof barrier material based on polymer polymer. The main points are: low density polyethylene (LDPE) geomembrane, high density polyethylene (HDPE) geomembrane and EVA geomembrane.

1. Wide, thickness specifications complete.

2. Has excellent environmental stress cracking performance and excellent resistance to chemical corrosion.

3. Excellent chemical resistance.

4. Has a large range of use temperature and a long service life.

5. Used in landfills, tailings storage sites, channel impermeability, dam impermeability and subway projects.

Mechanism.

Its main mechanism is to use the nonpermeable water-breaking dam leakage channel of plastic film, with its large tensile strength and elongation rate to withstand water pressure and adapt to the deformation of the dam body, while non-woven fabric is also a polymer short fiber chemical material, through needle ting or thermal lysaelectric forming, With high tensile strength and elongation, it not only increases the tensile strength and puncture resistance of plastic film, but also increases the friction coefficient of the contact surface due to the rough surface of the non-woven fabric, which is beneficial to the stability of the composite geomembrane and protective layer. At the same time, they have better resistance to bacteria and chemical effects, not afraid of acid, alkali, salt erosion, in the case of light-avoiding use, long service life.

Years.

In view of the composite geomembrane part of the site observation results synthetic materials in engineering applications have a certain anti-aging capacity, so some countries in some documents for its useful life has made a more lenient provisions, such as the former Soviet Union BCH07-74 "the application of polyethylene impermeable structure" provisions, polyethylene geofilm can be used in buildings with a service life of not more than 50 years. The conclusions of the article "Long-term characteristics of polypropylene composite geomembrane geosynthetic materials" published by the Austrian company Linz read: "The experience of field applications of polypropylene for more than 15 years shows that they have high chemical and biological stability; More than 100 years of stability can be expected.

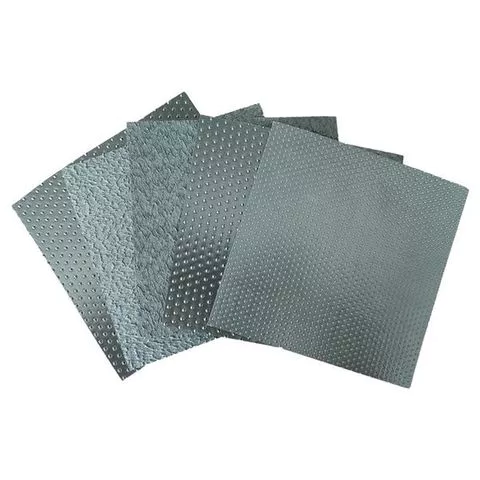

- textured geomembrane

Production Capacity:

Not informed

Delivery Timeframe:

Not informed

Incoterms:

Not informedPackaging Details:

Not informed

More about

Tai'an Luming Engineering Materials Company Limited

100-200

Employees

Not informed

Not informed

Year

Established

Business type

- Industry / Manufacturer

Keywords

- Geofilm geotechnical cloth.

Contact and location

-

skye ********

-

+86 1********

-

Taian / Shanfong | China