Description

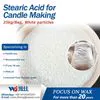

Stearic acid is a commonly used ingredient in candle making and plays a crucial role in the formulation of candles. Here's an overview of stearic acid's role and its benefits in candle production:

1. Wax Hardening: It is used to harden the wax and increase its melting point. This helps candles maintain their shape and structure, especially in warmer environments.

2. Enhances Burning Properties: It improves the burn quality of candles by slowing down the rate of combustion. This results in longer burn times and helps reduce dripping and excessive smoking.

3. Opacity and Color Enhancement: It can enhance the opacity of candle wax, especially when using translucent or colored waxes. It helps achieve a more vibrant and solid color appearance.

4. Mold Release Agent: It acts as a mold release agent, making it easier to remove the finished candles from their molds without sticking or damaging the shape.

5. Fragrance Retention: It can help improve the retention and diffusion of fragrance oils in candles. It allows the fragrance to bind more effectively with the wax, enhancing the scent throw during burning.

6. Stability and Shelf Life: The addition of stearic acid to candle wax can increase its stability and shelf life. It helps prevent the wax from discoloration, deterioration, or developing a stale odor over time.

7. Texture and Consistency: It can contribute to the smoothness and creaminess of the candle wax, improving its texture and consistency during the pouring and solidification process.

When using stearic acid in candle making, it is important to consider the appropriate dosage. Excessive amounts of stearic acid can lead to issues like excessive smoke, decreased scent throw, or poor burning performance. It is recommended to follow specific guidelines and conduct small test batches to determine the optimal amount of stearic acid based on the desired results.

Overall, stearic acid is a valuable ingredient in candle making, offering benefits such as wax hardening, improved burn quality, color enhancement, fragrance retention, and overall stability.

FAQs:

How much stearic acid is good for making candles with paraffin?

The proportion of stearic acid added can vary according to specific needs. If the purpose is to increase the hardness of the candle and reduce issues such as bubbles and cracking, an intermediate value, such as 5% to 10%, can be chosen. If it is for specific process effects, a higher proportion or even the maximum amount of addition may be required. However, to avoid excessive emulsification and other potential issues, it is not recommended to add more than 30%.

- Stearic Acid

- Candle

Production Capacity:

30000

Delivery Timeframe:

Immediate

Incoterms:

CFR - Cost and Freight

CIF - Cost, Insurance and Freight

EXW - Ex Works

FOB - Free on Board

Packaging Details:

25KG/BAG

More about

WJWAX COMPANY

50-100

Employees

10M - 50M

Sales volume (USD)

20%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

Keywords

- paraffin wax

- microcrystalline wax

- white oil

- mineral oil

- micro wax

- paraffin oil Ver Mais

Contact and location

-

Mr.Zheng ********

-

+86 1********

-

Jingmen City / Hubei | China