Description

Product Introduction: The substrate is an alloy coating of 55% aluminum, 43% zinc, and 1.6% silicon (density 3.75 g/cm³), combining the physical protection of aluminum with the electrochemical protection of zinc, offering 2-6 times the corrosion resistance of galvanized steel. Advantages: o Corrosion Resistance: No red rust after 5500 hours of salt spray testing (galvanized steel only 300 hours). o Heat Resistance: Can withstand long-term high temperatures of 315℃ (galvanized steel only 230℃). o Economy: 3% larger unfolded area than galvanized steel for the same weight. o High Heat Reflectivity: Up to twice that of galvanized steel, suitable for energy-efficient buildings.

- 55% Aluminum-Zinc Coil

- AZ150 Aluminum-Zinc Coil

- Aluminum-Zinc Steel Coil

- High-Temperature Aluminum-Zinc Coil

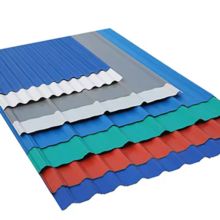

- Aluminum-Zinc Color-Coated Substrate

- Aluminum-Zinc Coil Material

- Aluminum-Zinc Alloy Steel Coil

- Aluminum-Zinc Anti-Corrosion Coil

- Aluminum-Zinc Coil Manufacturer

- Aluminum-Zinc Coating for Building Roofing

Production Capacity:

900000

Delivery Timeframe:

Within 30 Days

Incoterms:

CIF - Cost, Insurance and Freight

EXW - Ex Works

FOB - Free on Board

Packaging Details:

Not informed

More about

SHANDONG JULONG PREPAINTED STEEL CO.,LTD

200-500

Employees

10M - 50M

Sales volume (USD)

80%

% Export sales

Year

Established

Business type

- Industry / Manufacturer

- Distributor / Wholesaler

- Retailer

Keywords

- Slitting

- color coated coil

- galvanized coil

- color aluminum coil

- printed color coated coil

- color profiled tile

- nano heat insulation board

- aluminum-zinc sheet Ver Mais

Contact and location

-

Daoxiu ********

-

+86 8********

-

binzhou / shandong | China