More about

iNOEX GmbH

100-200

Employees

10M - 50M

Sales volume (USD)

Not informed

Year

Established

Business type

- Industry / Manufacturer

Keywords

- gravimetric weighing

- gravimetric dosing

- dosing

- level monitoring

- radar measuring system

- ultrasonic measuring system

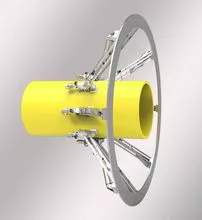

- x-ray measuring system

- terahertz measuring system

- wall thickness inspection

- data management Ver Mais

Contact and location

-

Marcel ********

-

+49 54********

-

Melle / Lower Saxony | Germany